Joyce manufactures a range of industrial foams with cutting edge conversion technologies to suit a variety of specialised applications.

Industrial.

-

We offer foams built to perform in tough environments. Our Polyether foams resist water and humidity, whereas our Polyester foams provide chemical resistance for use in automotive and filtration applications.

-

We manufacture combustion-modified foams which do not contain any liquid fire retardants, offering fire safety without compromising the health of our environment.

-

Our acoustic solutions deliver quiet where it’s needed most. Whether your project calls for sound baffles or anechoic wall tiles, we have a solution.

Industrial Solutions.

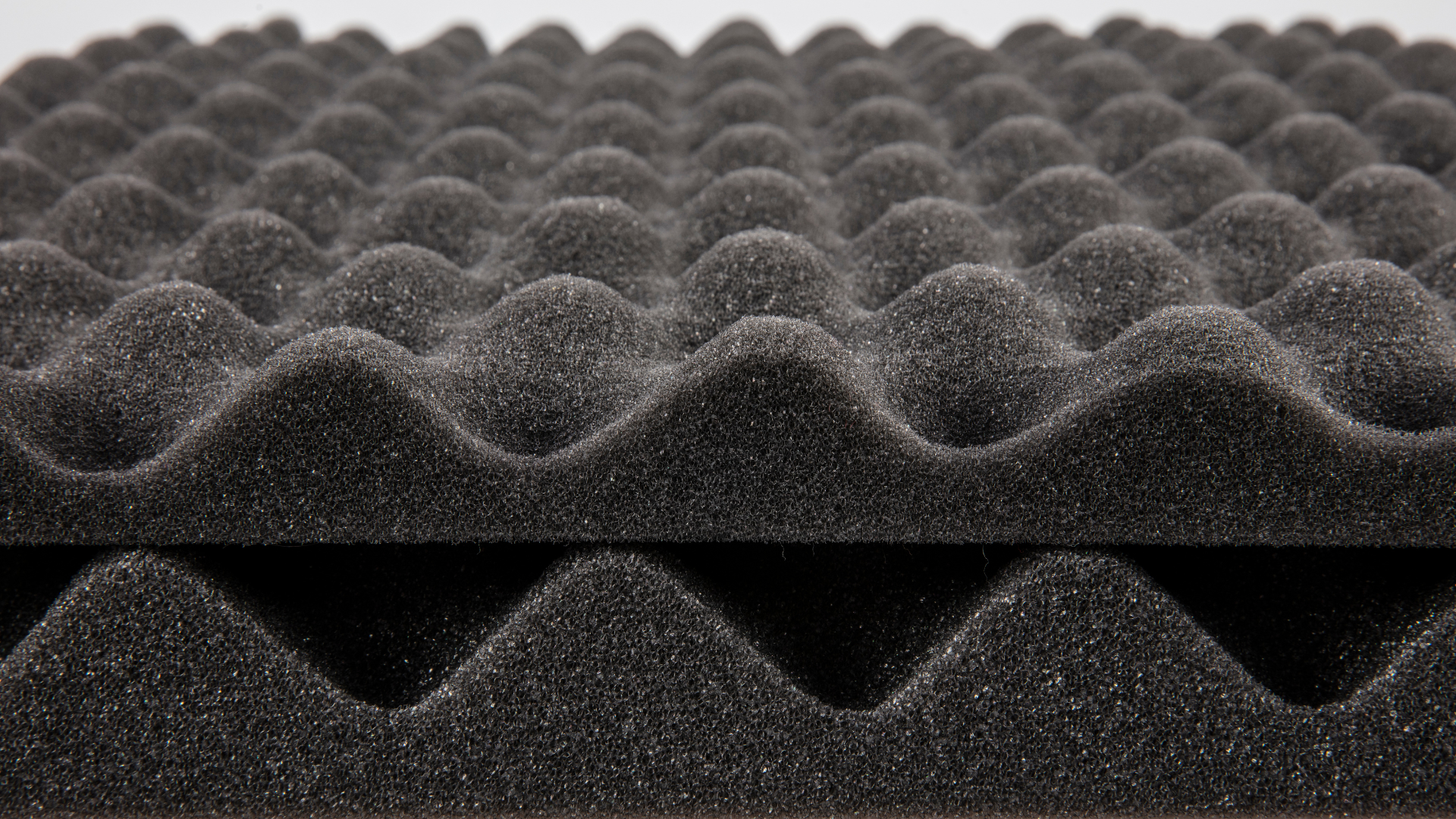

Acoustic Foam

Acoustic foam tiles cut in an anechoic wedge pattern to absorb sound waves.

Packaging Foam

Our packaging foam absorbs shocks and can be custom cut to fit a specific product.

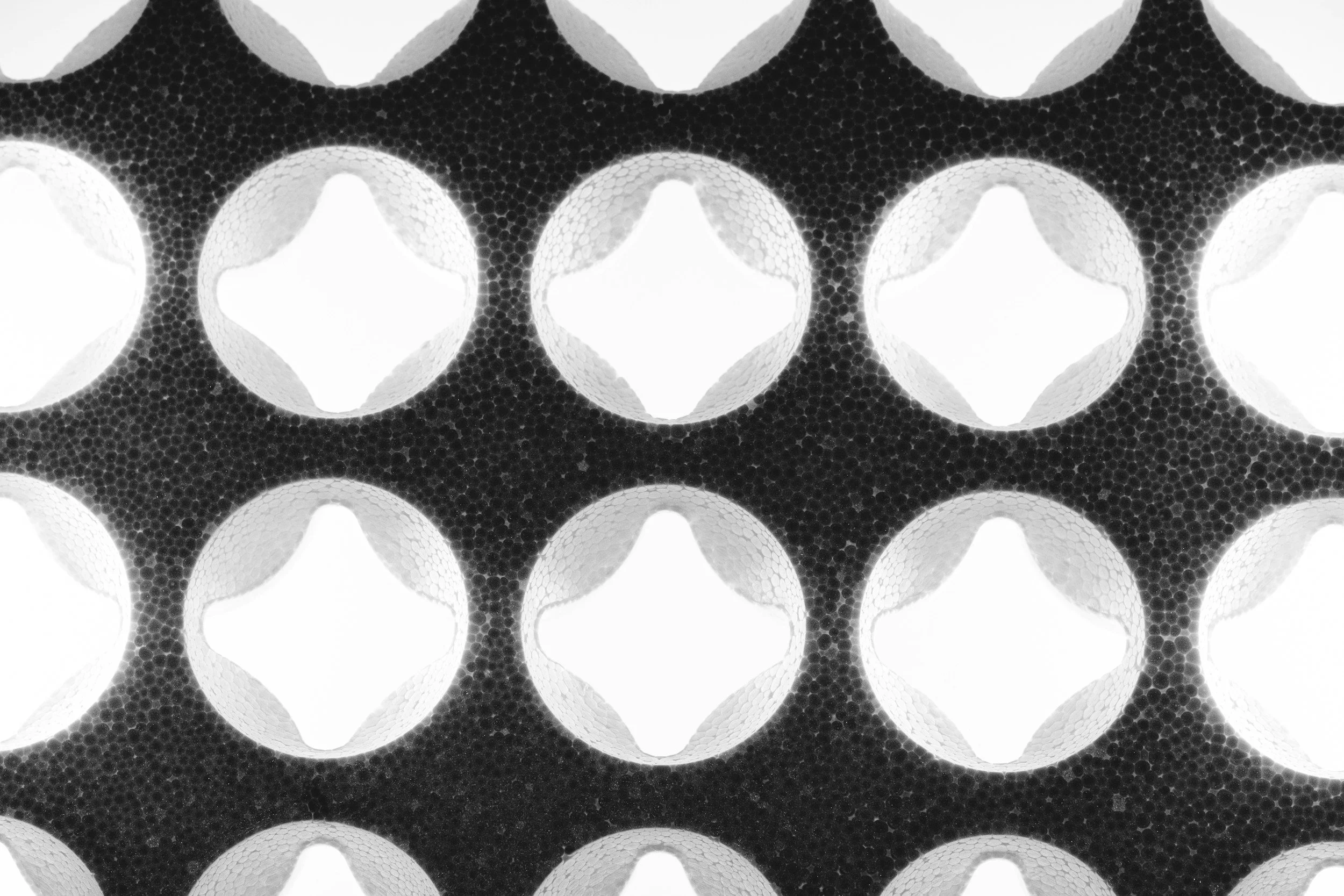

Reticulated (Filter) Foam

Our reticulated foams are designed for industrial filtration, suitable in both chemical and water based environments.

Weather Strips & Backing Rods

High-quality weather strips and backing rods designed to seal, insulate, and protect across industrial applications.

The Healthier Choice

Global GreenTag is a globally recognised and trusted ecolabel that independently certifies products to ensure they meet strict international environmental and performance standards.

The GreenRate™ certification is awarded in tiers, with Level A certified products reflecting the highest commitment to the global environmental and performance standards adopted by the GreenRate™ scheme.

The Global GreenTag GreenRate™: Level A certification has been awarded to the majority of the Joyce Foam range.