Innovation

At the core of everything we do.

Global

R&D

Material

Science

Manufacturing Technology

Conversion Technology

As part of a Global Group, we have access to the industry’s best innovations.

Our chemists and engineers are here to ensure our products are fit for your specific purpose.

Our state-of-the-art technologies give you access to the best and widest range of materials in the market.

Our conversion capabilities allow you to create unique products and more differentiated value propositions.

Global Research & Development

As part of one of the largest comfort groups in the world, we have access to the industry’s best innovations and state-of-the-art R&D facilities.

The Joyce lab in Sydney provides local agility while our centralised R&D lab in Delhi provides global sophistication.

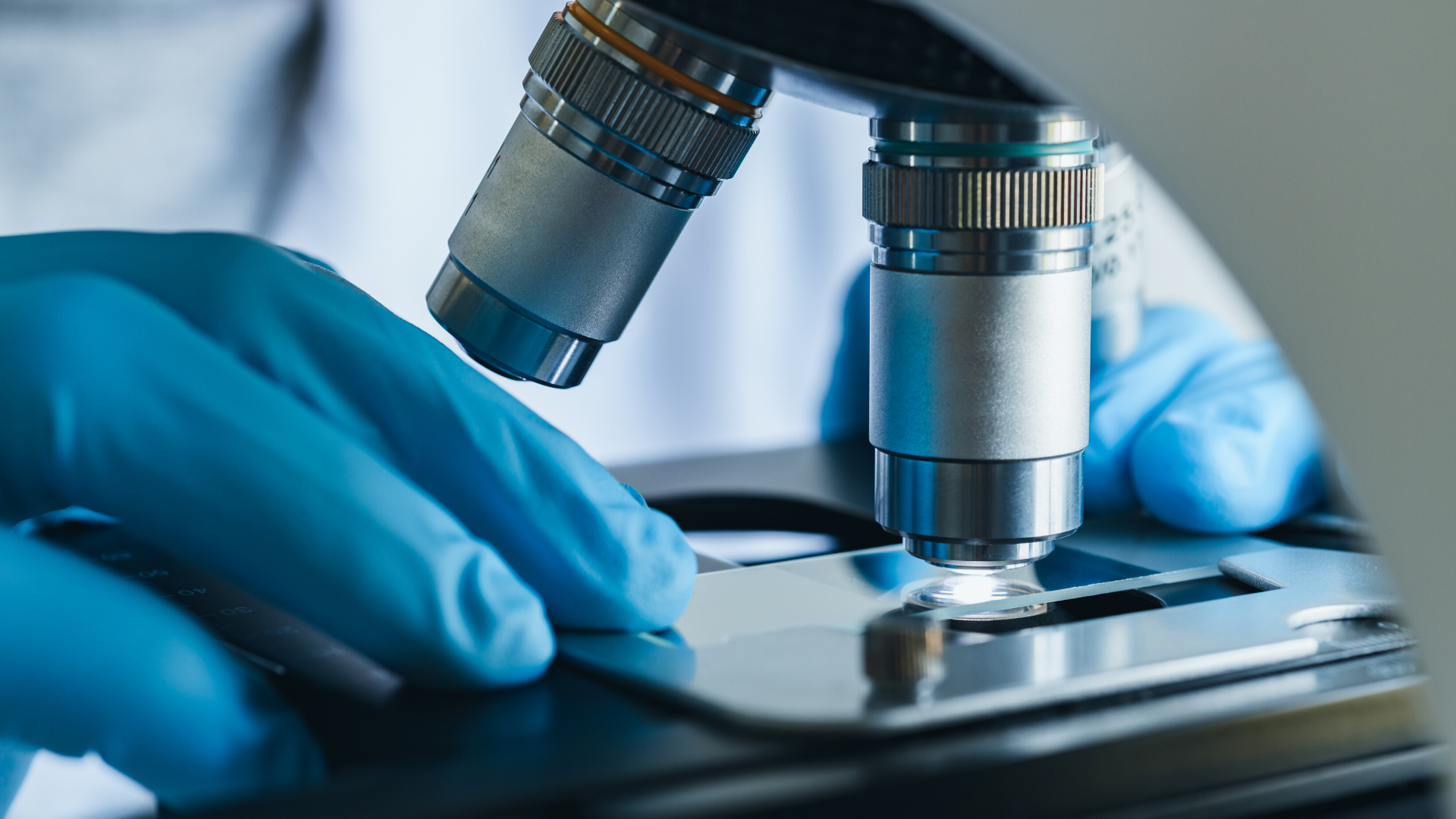

Material Science

Joyce has one of the most comprehensive and advanced soft materials labs in Australia. Our team of chemists and engineers is here to support your R&D efforts while also ensuring our quality assurance processes are world class.

Located in Sydney, the Joyce lab is equipped for R&D and testing in: product fit for purpose assessments, pressure mapping, microclimate testing, heat and humidity management, durability, fire safety, and more.

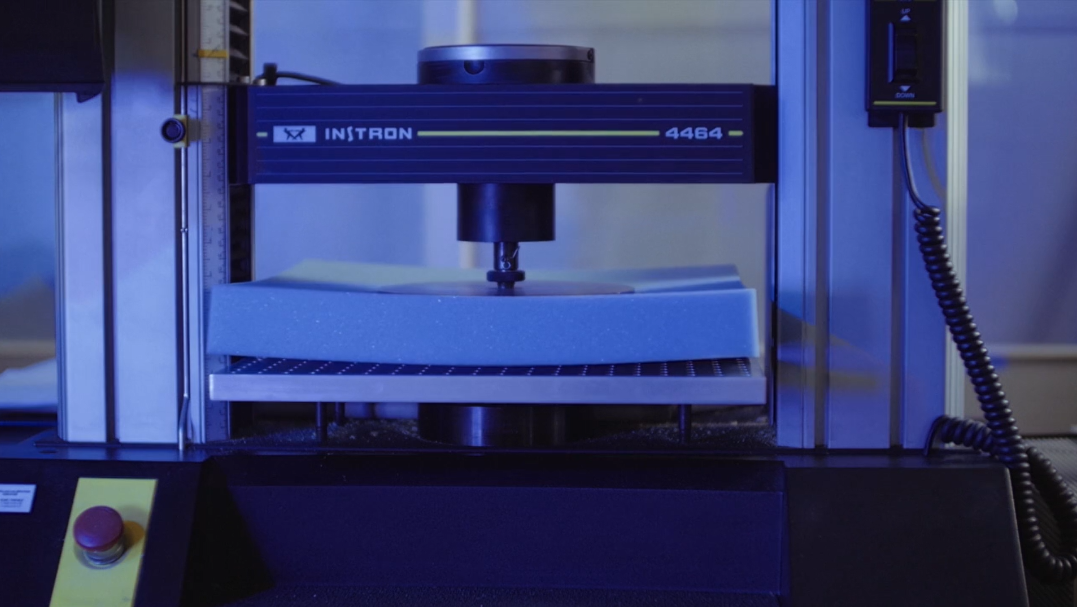

Manufacturing Technology

Through the use of VPF technology, Joyce is able to produce materials which cannot be made with traditional foaming equipment. This gives our customers access to the widest range of foam products – softer, harder, higher and lower density materials which can only be produced with VPF.

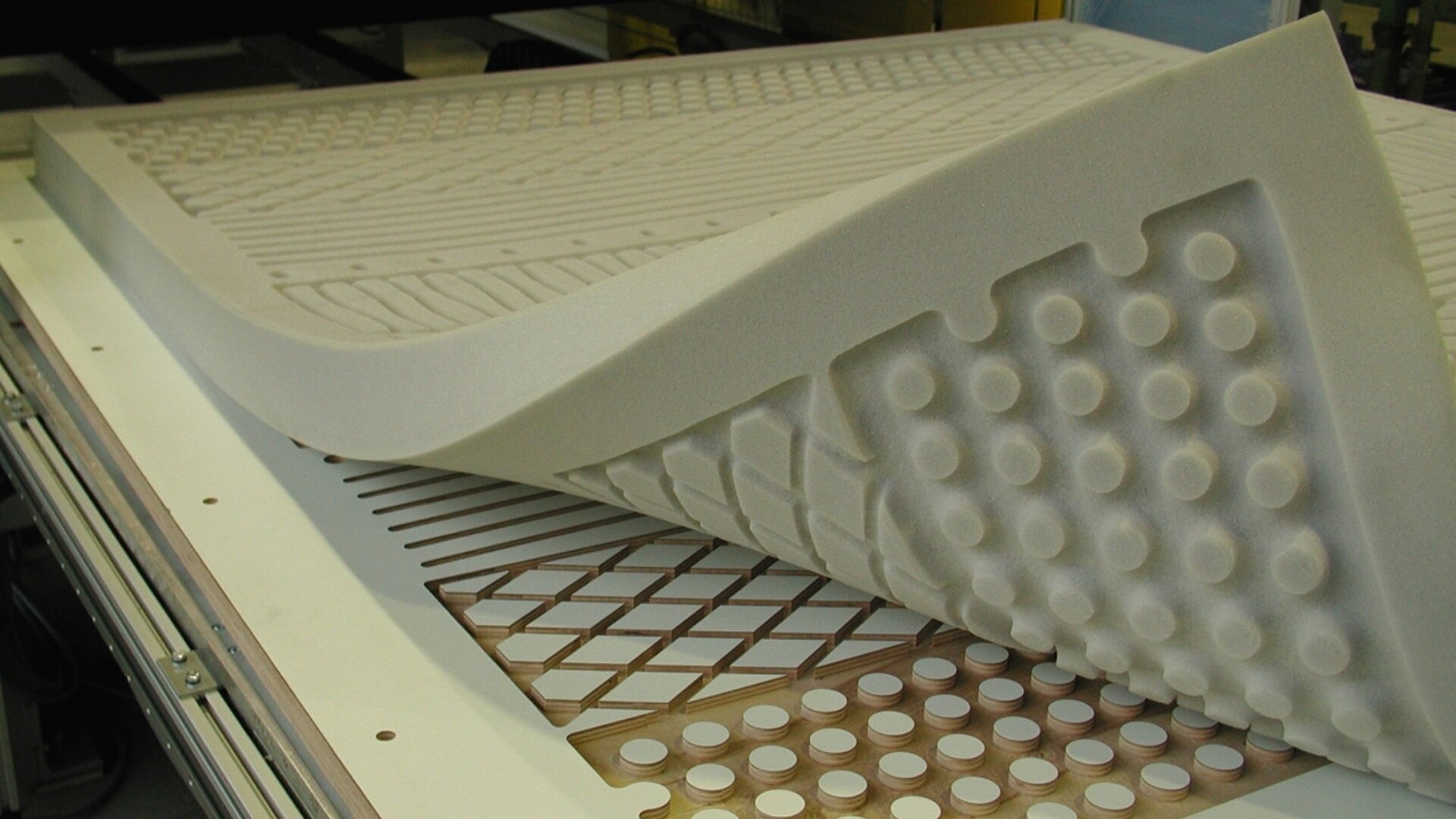

Conversion Technology

To help you fully leverage our materials, we’re equipped with a range of specialised technologies in foam cutting and conversion. These processes allow you to create unique products and selling propositions that help strengthen your competitive advantage.

These technologies include: an automated mattress core assembly line, 3D surface modification, CNC drilling and ventilation, dual-axis CNC cutting, 3D printing, and more.